How Computer Vision Prevents Quality Losses in High-Speed Beverage Production.

High-speed beverage bottling lines operate under extreme pressure. With thousands of units produced per hour, even minimal deviations in filling, sealing, or labeling can quickly scale into significant quality losses. In these environments, manual inspection and traditional rule-based vision systems are no longer sufficient.

“As beverage manufacturers face increasing pressure to improve efficiency, traceability, and uptime, real-time quality intelligence is becoming a strategic requirement, not just a quality function.”

Computer vision enables continuous, real-time inspection across bottling lines, identifying defects early and preventing scrap, rework, and downstream disruptions. For large-scale beverage producers, this capability is becoming a core component of operational excellence.

The Structural Challenge of High-Speed Beverage Bottling

Modern bottling operations share a set of structural constraints:

- Line speeds that exceed human inspection capability

- Tight regulatory and quality tolerances

- Multiple SKUs and frequent changeovers

- Mechanical wear that evolves gradually, not abruptly

- High cost of downstream quality failures

Most quality issues do not originate from a single failure. They emerge from small process drifts that remain invisible until losses accumulate.

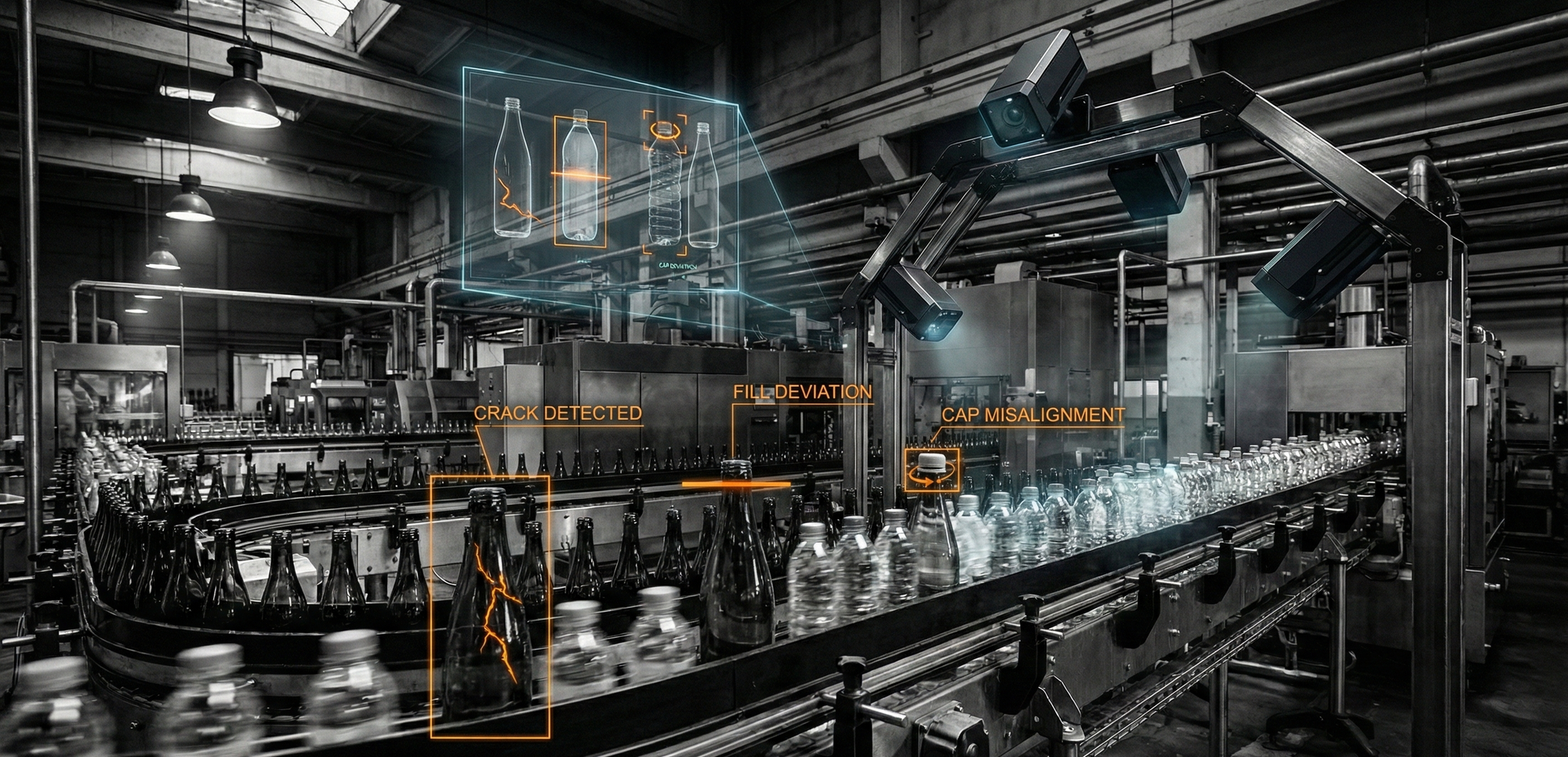

Common defects in beverage bottling environments include:

- Micro-fractures in containers

- Fill-level variation outside tolerance

- Cap misalignment or improper sealing

- Label placement or adhesion errors

- Contamination or surface anomalies

When detection happens late, entire production runs may be affected.

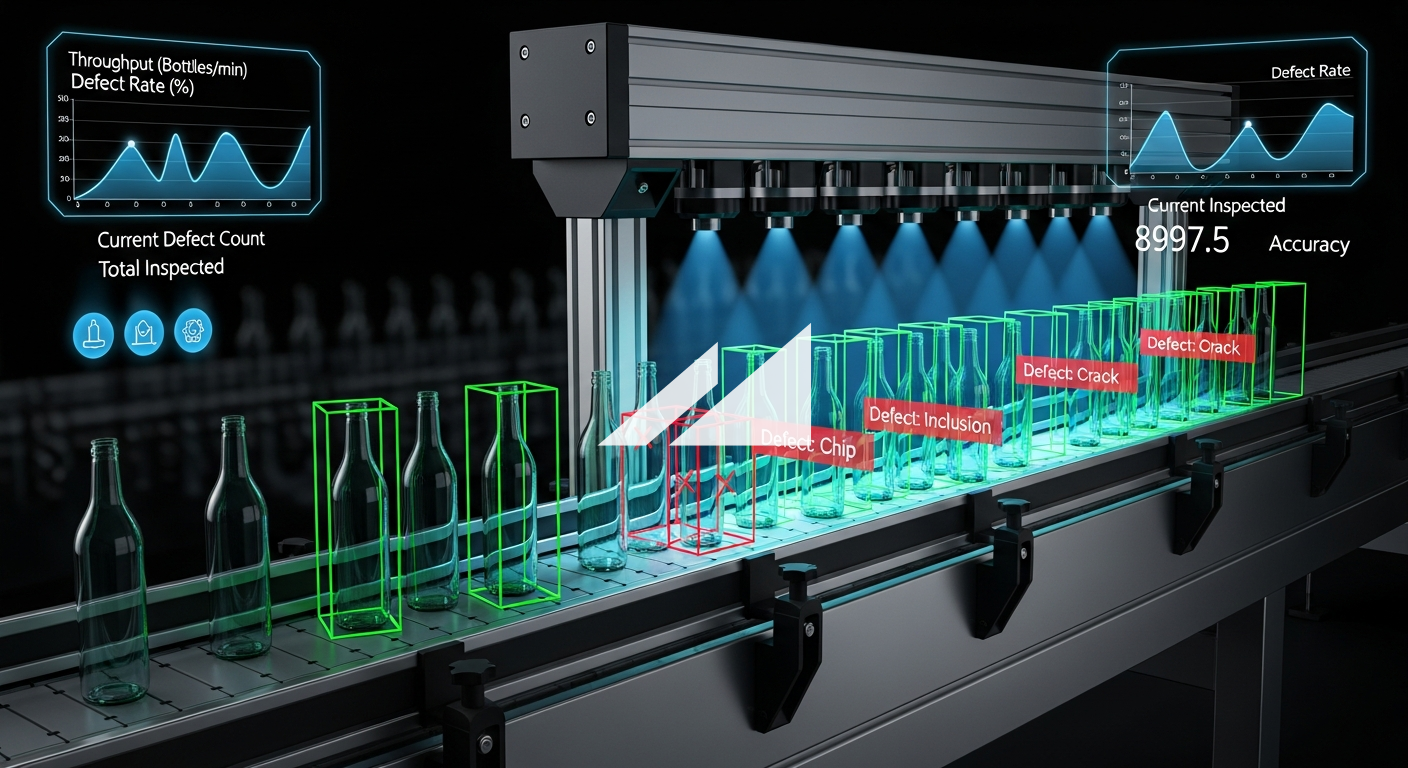

How Computer Vision Detects Defects in Real Time

AI-based computer vision systems analyze visual data captured directly on the production line. Trained on real production variability, these models detect anomalies without relying on rigid thresholds.

In beverage bottling lines, computer vision typically performs:

- Container surface inspection

- Fill-level verification

- Closure and seal validation

- Label position and quality checks

High-Speed Inspection Without Slowing the Line

Bottling lines often operate at hundreds of units per minute. Any inspection system must keep pace.

Edge-deployed computer vision systems process images at hundreds of frames per second, enabling:

- Immediate defect identification

- Zero production latency

- Real-time alerts to operators

- Automatic classification and traceability

This transforms quality control from a sampling-based activity into a continuous process.

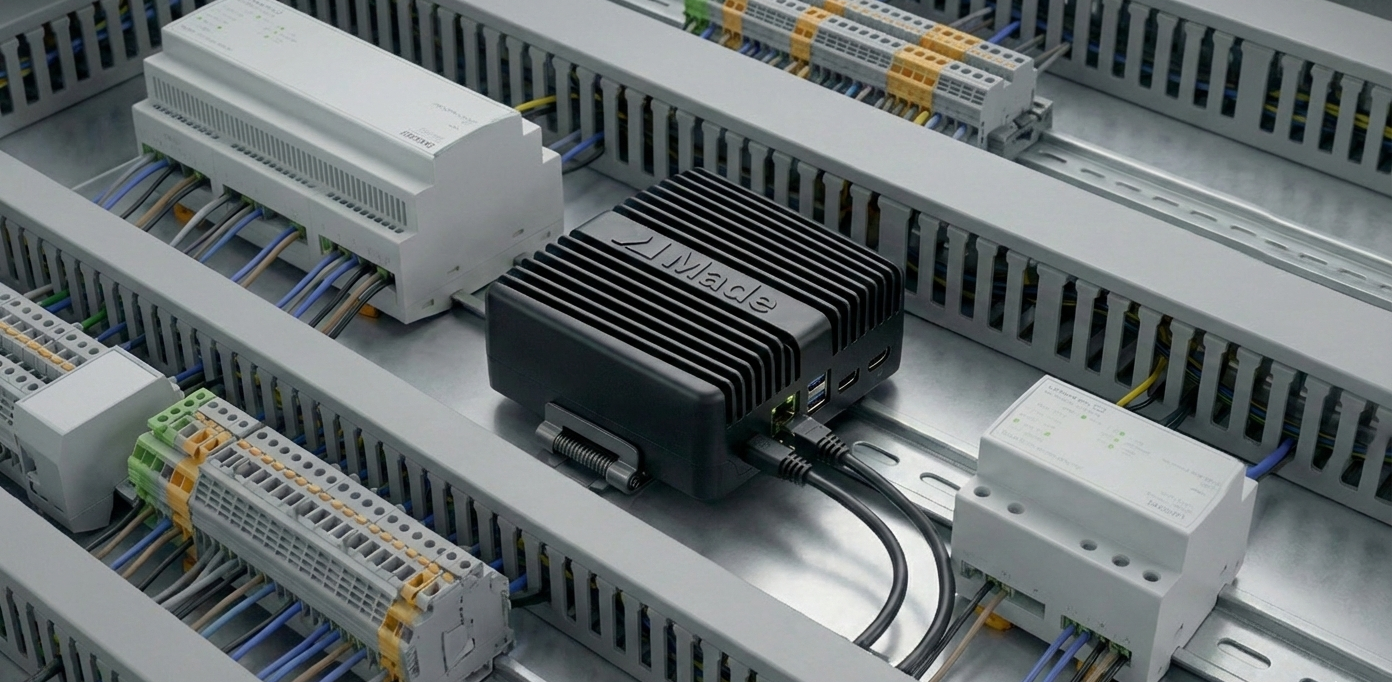

Why Edge AI Is Critical in Beverage Manufacturing

Cloud-only architectures introduce latency, connectivity risk, and data governance challenges. Beverage bottling operations require deterministic performance and full control.

Edge AI enables:

- Real-time processing directly on the line

- Autonomous operation during network interruptions

- Compliance with data privacy and security requirements

- Predictable response times for critical decisions

By running AI models at the edge, inspection remains aligned with production speed and reliability requirements.

Source : NVIDIA

Preventing Scrap Before It Scales

The real value of computer vision lies in trend detection, not just rejection.

By continuously analyzing defect patterns, AI systems can:

- Identify gradual misalignment or wear

- Detect early signs of sealing degradation

- Surface recurring issues across shifts

- Enable preventive interventions before scrap escalates

This allows teams to correct root causes instead of reacting to finished-goods losses.

What Large Bottling Operations Typically Achieve

Across high-volume beverage lines, computer vision deployment commonly leads to:

- Reduced scrap and rework

- Improved line stability

- Higher consistency across operators and shifts

- Faster root cause identification

- Stronger auditability and traceability

Impact is visible early, often within the first weeks of operation.

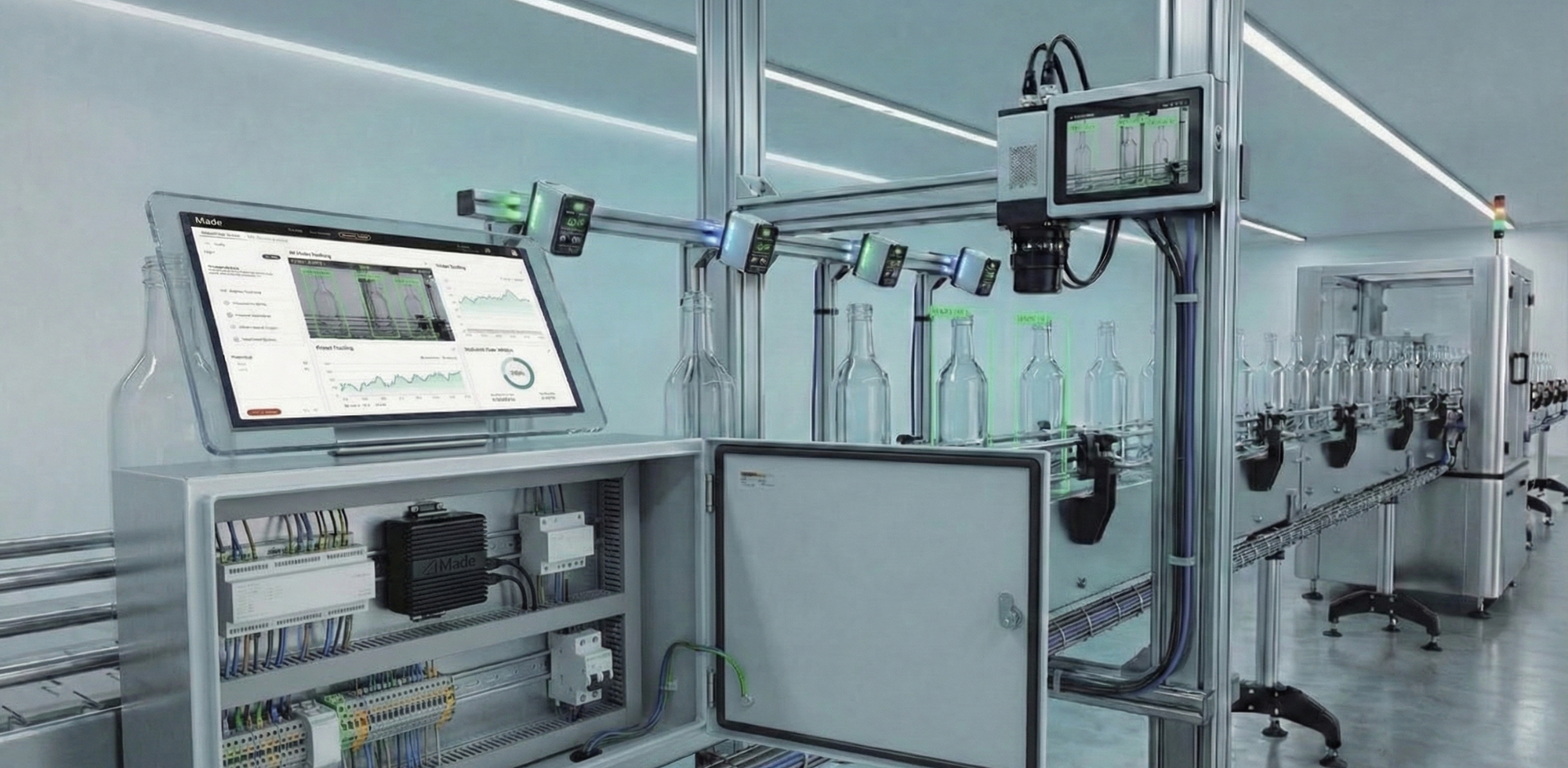

Deploying Computer Vision Without Disrupting Operations

Enterprise bottling plants cannot afford downtime for experimentation. Modern systems are designed to layer intelligence on top of existing infrastructure:

- No PLC replacement

- No changes to line mechanics

- No disruption to MES or ERP systems

Cameras and edge devices operate alongside the line, augmenting visibility without interfering with production.

“Detecting defects is only the first step. The real transformation begins when visual data is continuously connected to production context, operational decisions, and preventive action.”

From Defect Detection to Industrial Intelligence

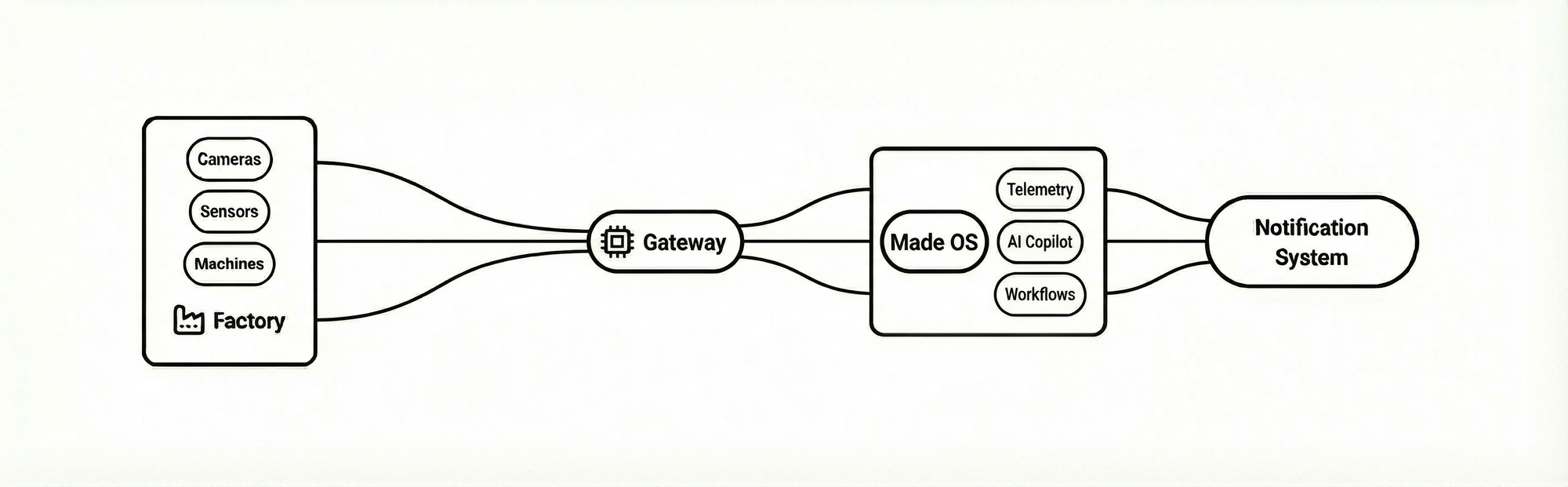

Visual inspection is often the entry point to a broader intelligence layer. Once visual data is captured in real time, it can be correlated with:

- Machine states

- Environmental conditions

- Production schedules

- Maintenance events

This enables predictive quality, operational optimization, and data-driven continuous improvement.

FAQs — Computer Vision in Bottling Lines (AEO)

What types of defects can computer vision detect in bottling lines?

Computer vision can detect container cracks, fill-level deviations, cap and seal issues, label misalignment, and surface contamination in real time.

Can computer vision work at very high line speeds?

Yes. Modern edge-based systems process hundreds of frames per second, enabling inspection at full bottling speed without slowing production.

How is AI inspection different from traditional vision systems?

AI-based systems adapt to natural variation and detect subtle anomalies, while traditional systems rely on fixed rules that struggle with variability.

Does computer vision replace human inspectors?

No. It augments operators by providing continuous inspection and early warnings, allowing humans to focus on corrective actions and decision-making.

Can computer vision be deployed without replacing existing equipment?

Yes. Most systems integrate with existing bottling lines without modifying PLCs, machinery, or control systems.

How quickly can results be seen after deployment?

Many operations observe reduced scrap and improved visibility within weeks, as defects are detected earlier and trends become visible.

Final Perspective

In high-speed beverage bottling, quality issues propagate faster than manual processes can respond. Computer vision brings real-time awareness to the production floor, allowing manufacturers to prevent losses, stabilize operations, and scale quality with confidence.

As bottling complexity increases, AI-driven inspection is becoming a foundational capability for competitive beverage manufacturing across the Americas.

“This shift—from reactive inspection to real-time industrial intelligence—is defining the next generation of high-performance manufacturing across the Americas.”

From Insight to Implementation

While computer vision is often introduced as a quality tool, its real value emerges when it becomes part of a broader industrial intelligence layer. Evaluating how inspection, edge processing, and production context interact is key to unlocking preventive quality at scale.